Speed isn’t just a competitive advantage anymore — it’s an expectation. In an era where customers want everything yesterday, the ability to move goods quickly and efficiently through your supply chain can define your success. That’s where Industry 4.0 comes in.

From supply chain automation and predictive analytics to robotics and AI, Industry 4.0 is reshaping how businesses operate. These technologies are helping companies boost visibility, streamline processes, and unlock new levels of speed and efficiency across every stage of the supply chain.

So, how exactly does it work — and what’s the best way to bring these innovations into your operations? Let’s break it down.

Related Reading: How to streamline complex engineering supply networks

What is Industry 4.0

Think of Industry 4.0 as the digital transformation of supply chains. It’s the fourth industrial revolution — powered by smart, connected technologies like the Internet of Things (IoT), artificial intelligence (AI), robotics, big data, and cloud computing.

The goal? To create a supply chain that’s not just fast, but intelligent — one that anticipates problems, adapts in real time, and keeps operations flowing seamlessly.

By connecting every part of your network — from warehouses to transport fleets — these tools give you the insights and automation you need to respond to challenges before they even arise.

Related Reading: Why FMCG supply chains fail—and how tech saves them

How Industry 4.0 is Redefining Supply Chain Management

Let’s take a closer look at some of the biggest ways these technologies are transforming supply chain management:

1. Smarter Visibility with IoT

IoT devices act as your digital eyes and ears across the supply chain. These connected sensors monitor inventory, track shipments, and even assess equipment health — all in real time.

That means you can see where every product is, when it will arrive, and what condition it’s in. For technology supply chain management, this level of visibility is game-changing — giving managers the data they need to make faster, better decisions.

2. Predictive Power with AI and Machine Learning

AI takes data and turns it into foresight. By analysing patterns across huge datasets, AI can forecast demand, flag inefficiencies, and predict disruptions before they happen.

Imagine knowing in advance that a certain route will face delays or that demand for a product is about to surge. With AI-driven planning, you can adapt instantly — keeping your operations agile and your customers happy.

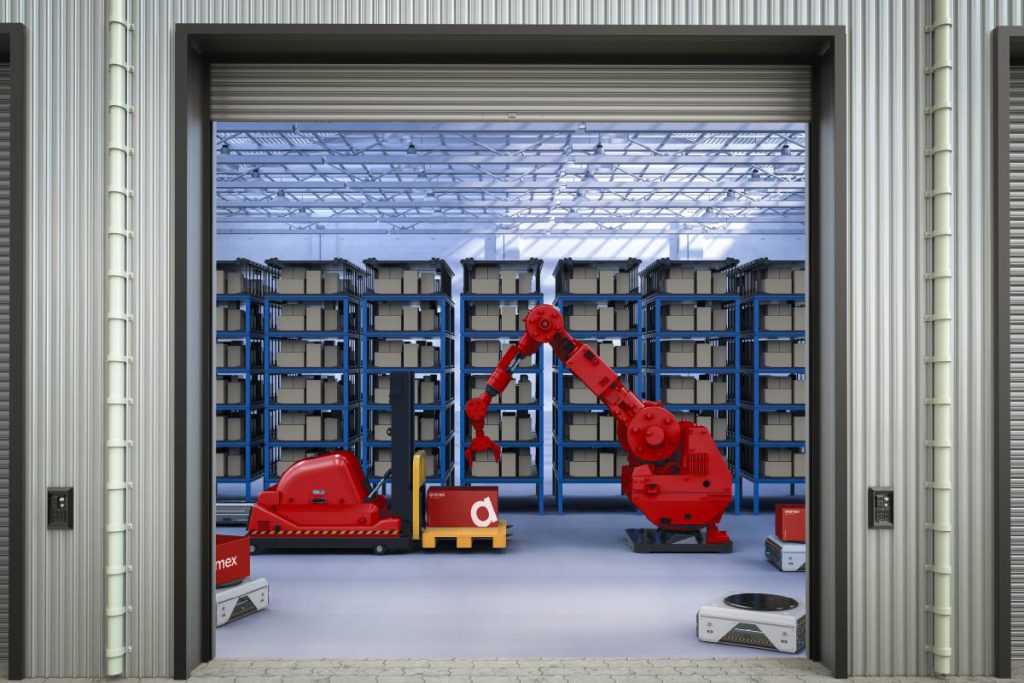

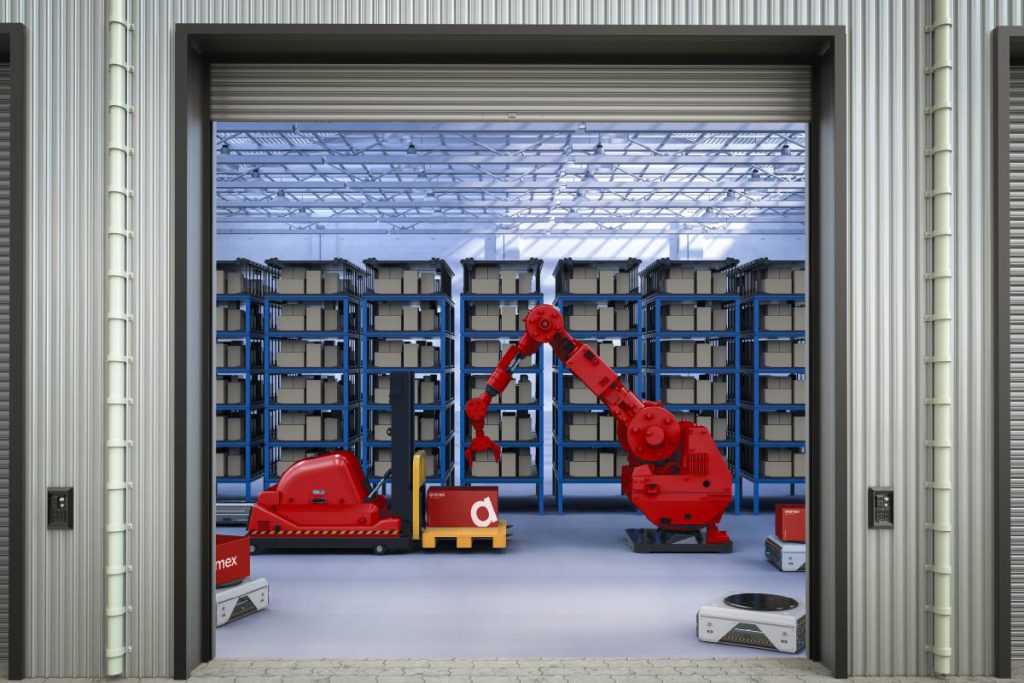

3. Automation That Never Sleeps

Supply chain automation is one of the biggest accelerators of efficiency. From robots handling picking and packing to automated conveyor systems and self-driving forklifts, automation enables 24/7 productivity.

This isn’t just about speed — it’s also about precision. Fewer manual processes mean fewer mistakes, faster fulfilment, and lower operational costs.

4. Insights That Drive Action

Big data analytics help transform raw information into actionable insight. By understanding trends across sourcing, production, and logistics, you can identify bottlenecks and continuously refine your processes.

It’s not about collecting more data — it’s about using it intelligently. Advanced analytics make it easier to forecast demand, manage risks, and measure performance, all while supporting faster, more confident decision-making.

The Business Impact: Why Industry 4.0 Matters

When done right, technology supply chain management delivers tangible results. Here’s how businesses are seeing the benefits:

- Real-time visibility: Track every shipment and movement across your network.

- Agility under pressure: Make quick, informed decisions when disruptions hit.

- Lower costs: Reduce waste, minimize labor, and optimize routes.

- Happier customers: Deliver on time, every time — with transparency and reliability.

Related Reading: The hidden costs of poor airline supply planning

Putting Industry 4.0 into Practice

Adopting these technologies doesn’t happen overnight. It’s a journey — and one that starts with strategy.

Step 1: Assess Your Current Supply Chain

Identify weak points, inefficiencies, and data gaps. Understanding where you are now helps you build a roadmap for where you want to go.

Step 2: Build a Technology Roadmap

Outline which Industry 4.0 tools will deliver the most impact. Prioritise areas like automation, visibility, or data analytics — and plan your rollout carefully with budgets and timelines in mind.

Step 3: Train and Upskill Teams

New tools need new skills. Invest in training so your team can make the most of the technology. Change management is just as important as the tech itself.

Step 4: Partner with the Right Providers

Collaboration is key. Work with trusted technology and logistics partners who understand the complexities of modern supply chain management. They can help integrate tools seamlessly and ensure everything runs as one connected system.

Related Reading: The biggest shifts in automotive logistics right now

Key Takeaway: Be 4.0 Ready – Transform, Accelerate, Lead

The next evolution of supply chain management is here — powered by automation, data, and intelligent connectivity.

By embracing Industry 4.0, businesses can transform traditional operations into agile, data-driven ecosystems that move faster, cost less, and serve customers better. Adopting these tools takes vision and planning, but the payoff is clear: a more resilient, responsive, and future-ready supply chain.

The future of logistics belongs to those who innovate. Let’s build a smarter, faster supply chain together.