Manufacturing logistics is an inherently complex and demanding discipline. From inventory control and production scheduling to transportation management and technology integration, it requires precision, coordination, and continuous oversight. Any disruption in one area can quickly create operational inefficiencies that compromise delivery schedules, increase costs, and affect customer satisfaction.

Many of these inefficiencies remain hidden, only surfacing when delays, rising expenses, or service issues occur. For manufacturing organisations seeking to improve performance, the first step is identifying these bottlenecks and addressing them with targeted strategies.

Related Reading: Is your supply chain holding back production growth?

Inventory Management: Precision Beyond Stock Levels

Effective inventory management in manufacturing logistics is a careful balancing act. Excess stock ties up capital and occupies valuable space, while insufficient inventory risks production delays and dissatisfied customers.

A frequent challenge is the poor integration of systems across procurement, production, and distribution. When data is fragmented, stored in separate spreadsheets or outdated platforms,coordination becomes inefficient.

The solution lies in implementing intelligent inventory management systems capable of delivering real-time updates, predicting shortages, and improving demand forecasting. While these systems require upfront investment, they can transform warehouse operations into efficient, data-driven environments that minimise waste and improve throughput.

Transport Complexities: Managing Multimodal Operations

In theory, combining rail, road, sea, and air transport can optimise delivery speed and cost. In practice, however, multimodal transportation often introduces challenges such as delays, compliance hurdles, infrastructure inconsistencies, and misaligned communication between providers.

To address these issues, manufacturers can adopt advanced transportation management systems (TMS). These platforms provide route optimisation, real-time shipment tracking, seamless customs integration, and efficient mode switching. The result is a more reliable and predictable transportation network that reduces uncertainty and strengthens delivery performance.

Related Reading: Smarter supply chains: How tech is transforming auto logistics

Technology as a Competitive Differentiator

In modern industrial engineering logistics, data and technology are central to operational excellence.

Analytics: Enabling Data-Driven Decisions

Predictive analytics solutions analyse supply chain data to identify emerging demand patterns, anticipate disruptions, and inform proactive decision-making. However, the quality of these insights depends on the quality of the data itself, making robust data infrastructure and team training essential.

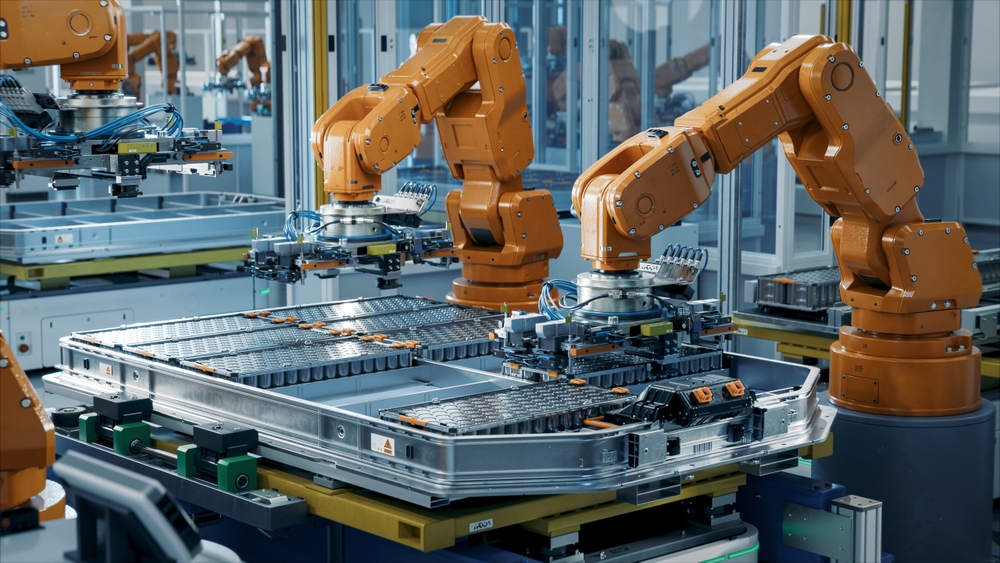

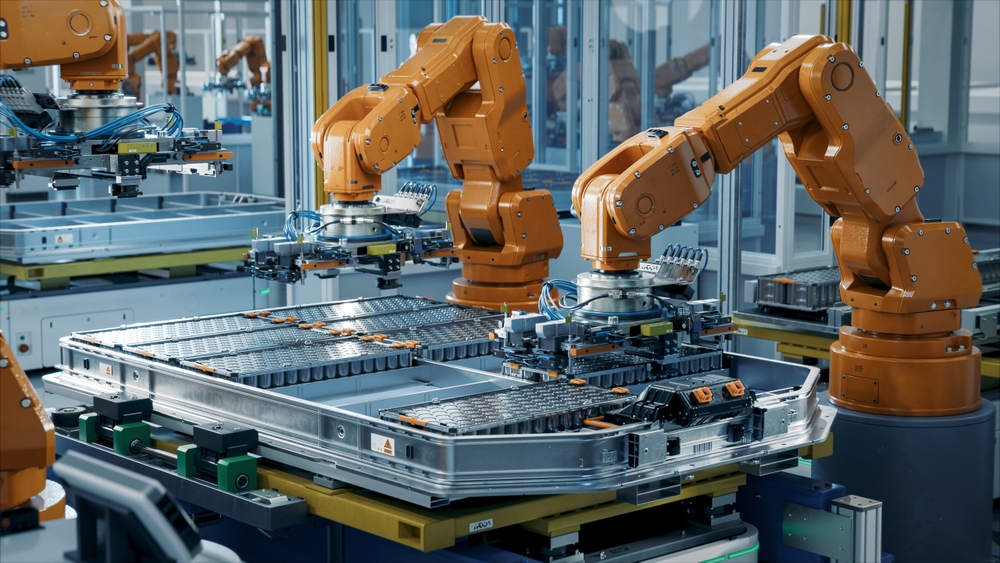

Automation and Robotics: Enhancing Speed and Accuracy

Automation technologies and robotics are no longer niche solutions. From warehouse material handling to order picking, packing, and shipping, they increase speed, reduce error rates, and improve cost efficiency.

Successful implementation, however, requires thoughtful change management. Staff training, workflow redesign, and role adaptation are necessary to ensure technology complements human capability rather than replacing it in isolation.

Related Reading: How to build a resilient supply chain that thrives amid disruptions

The Big Picture: Supply Chain Management in Manufacturing

Ultimately, effective supply chain management in manufacturing depends on two key principles: visibility and collaboration.

Visibility: Eliminating Operational Blind Spots

Without end-to-end visibility, delays and disruptions can go undetected until they have already impacted operations. Technologies such as IoT and blockchain now make it possible to track materials and products throughout the supply chain in real time, enhancing responsiveness and control.

Collaboration: Building Integrated Partnerships

Operational silos are increasingly incompatible with modern manufacturing demands. Integration between manufacturers, suppliers, logistics providers, and partners fosters aligned objectives, stronger communication, and reduced inefficiencies. Achieving this requires both advanced collaborative platforms and a culture built on trust and shared goals.

Preparing for the Future: Resilience as a Core Competency

Manufacturing supply chains will continue to face external pressures, including global market volatility, cost inflation, and rapid technological change. Building resilience is essential.

This means diversifying suppliers, establishing contingency plans, and remaining agile in the face of disruption. Emerging technologies such as AI and machine learning will continue to redefine what is possible in logistics – and the organisations that adapt early will have a clear competitive advantage.

Related Reading: Exploring the future of supply chain transparency with blockchain technology.

Key Takeaway: Strengthening Manufacturing Logistics for Long-Term Performance

Hidden inefficiencies can quietly erode profitability and damage brand reputation. By investing in advanced technologies, enhancing visibility, and fostering collaborative supply chain relationships, manufacturing businesses can transform these weaknesses into strategic strengths.

The future of manufacturing logistics belongs to organisations that treat efficiency and innovation as ongoing imperatives, ensuring that operations remain resilient, responsive, and ready for the demands of a competitive marketplace. Ready to rewire your supply chain for success? It’s time to take manufacturing logistics – and your entire operation – to the next level. Click here.